Tips for Performing Successful Tensile Testing

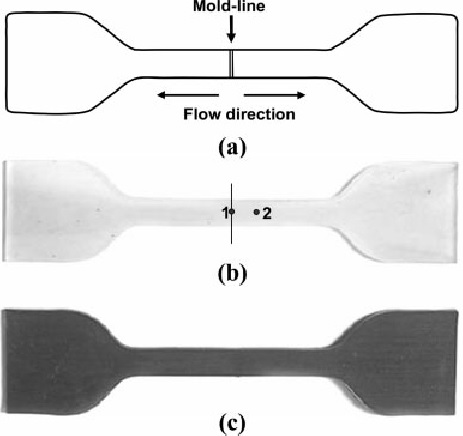

Tensile testing is very commonly performed test in different industry verticals. There are different challenges in this test to get accurate test results. One of the biggest challenges is to grip the sample in such a way so that tension can be applied in right manner. Due to inappropriate clamping, the tension concentrates around the area from where the sample is gripped. The solution to this problem is preparing a perfect sample. Whether it’s rubber or metal, a dumb-bell shaped sample is prepared. With this, the area that is clamped is kept wider and rest of the area is narrow. Thus, stress is calculated from the minimum cross section area.

How to Clamp the Sample in Right Way?

Presto gives vice grips as standards along with the tensile testing machine. These grips are usually suitable for samples like rubber, metal, thread and fibre. Here the major concern is, preparation of the sample and its clamping. A dumb-bell shaped sample is prepared and clamped in the grip. While clamping, it has to be made sure that wide area of the dumb-bell is fully clamped. If half of the wide area is clamped, it would lead to the dispersion of the tension throughout the sample. Whereas, the tension should concentrate on a narrow area.

The same principle applies to metal testing. The necking should appear in the narrow area, not at the edges.

Treatment of Sample Before Testing

According to the intended application of the material, the treatment of sample is done. Say, a rubber is being used for gasket manufacturing of deep freezer. The sample will be tested for its tensile properties after cold treatment. Similarly, metal is more brittle when tested at room temperature. However, after treatment, the necking appears and sample elongates than expected. Some materials change their properties after treatment like heat, cold, ozone exposure, etc.

For this, many industries have installed other environmental chamber to assess the actual behaviour of the material in real working conditions.

Testing of Tensile or Compressive Properties?

Well, compression and tension are completely opposite. We cannot derive either of the properties from one known value. You must perform 2 tests separately to get tensile strength and compressive strength. Presto’s Tensile testing machine – Zeus Ultimo is a 2-in-1 machine. This machine can be operated in both tension and compression mode. Along with that, different grips can be considered for a different type of sample. Self-tightening grips, roller type grips, wedge type grip, roller type grip, compression plate are the options to choose from.

For more information, contact us.